Water Temperature Gauge Wiring Diagrams are essential tools for understanding the electrical connections and circuitry of a vehicle’s water temperature gauge. These diagrams provide a detailed visual representation of how the various components are connected and help mechanics troubleshoot electrical issues efficiently. By following the wiring diagram, mechanics can identify faulty connections, broken wires, or other issues that may be causing the water temperature gauge to malfunction.

Importance of Water Temperature Gauge Wiring Diagrams

- Helps in understanding the electrical system of the water temperature gauge

- Allows for efficient troubleshooting of electrical problems

- Ensures proper installation and connection of components

Reading and Interpreting Water Temperature Gauge Wiring Diagrams

Reading and interpreting water temperature gauge wiring diagrams may seem daunting at first, but with a little practice, mechanics can easily decipher the information presented. Here are some tips for effectively reading and interpreting wiring diagrams:

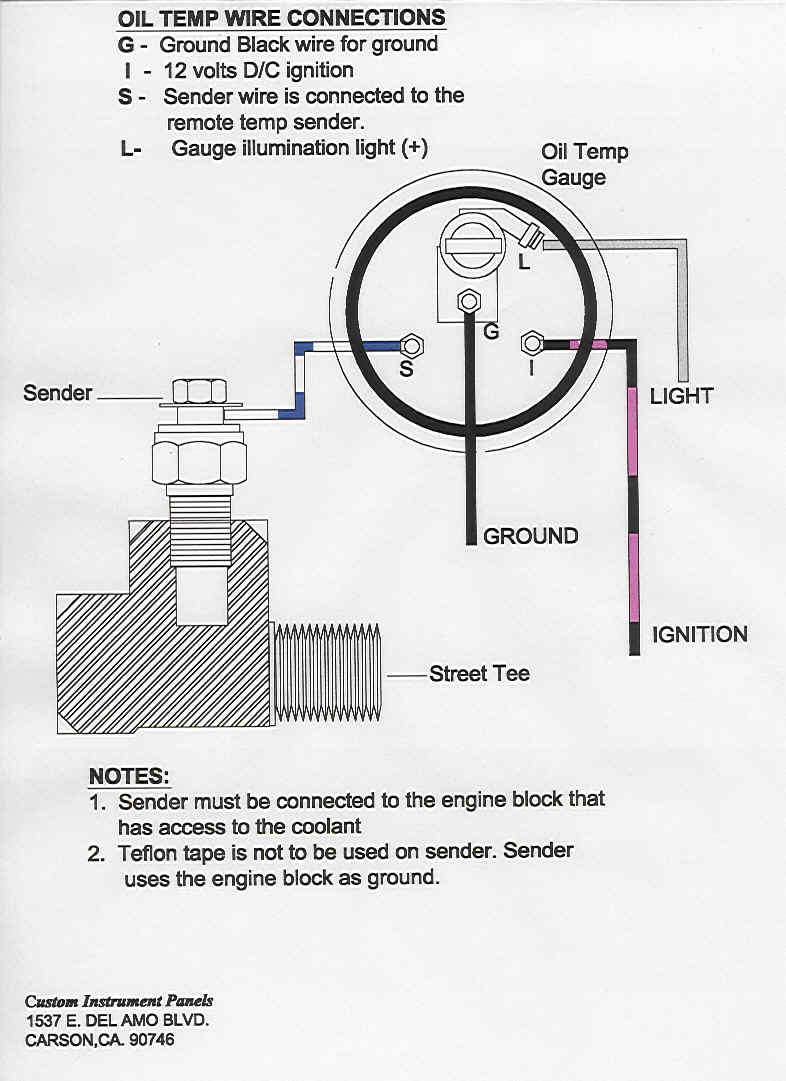

- Identify the components: Understand the symbols and colors used in the diagram to recognize different components.

- Follow the flow: Trace the flow of electricity from the power source to the gauge to understand how the circuit works.

- Check for continuity: Use a multimeter to check for continuity in the wiring to ensure there are no loose connections or breaks.

Using Water Temperature Gauge Wiring Diagrams for Troubleshooting

Water temperature gauge wiring diagrams are valuable tools for troubleshooting electrical problems related to the gauge. Mechanics can use these diagrams to:

- Identify faulty connections or wires causing the gauge to malfunction

- Locate short circuits or open circuits in the wiring

- Test the functionality of sensors and other components in the circuit

Importance of Safety

When working with electrical systems and using wiring diagrams, it is crucial to prioritize safety to prevent accidents or damage to the vehicle. Here are some safety tips and best practices to follow:

- Always disconnect the battery before working on the electrical system

- Use insulated tools to prevent electric shock

- Avoid working on the wiring when the engine is running

- Double-check connections and wiring before reassembling components

Water Temperature Gauge Wiring Diagram

Water Temperature Gauge Wiring Diagram For Your Needs

Installing oil temperature gauge out of Ram SRT10 – Dodge SRT Forum

Water Temp Gauge Wiring Diagram | Q&A for Electric Temperature Gauges

Hook up water temperature gauge | Installing Digital water temp gauge

Vdo Water Temp Gauge Wiring Diagram – Wiring Diagram Pictures

Technical: Wiring water temp. gauge – The FIAT Forum