When working on a restoration project or troubleshooting electrical issues on a vintage tractor like the M Farmall, having a clear and accurate wiring diagram is essential. The M Farmall Wiring Diagram provides a detailed illustration of the electrical system, showing the connections between various components and the flow of electricity throughout the system.

Why M Farmall Wiring Diagram are essential:

- Helps in understanding the electrical system of the tractor

- Aids in identifying faulty or damaged wiring

- Ensures proper installation of new electrical components

- Assists in troubleshooting electrical issues

How to read and interpret M Farmall Wiring Diagram:

Reading and interpreting a wiring diagram can seem daunting at first, but with a bit of practice, it becomes easier. Here are some tips to help you understand M Farmall Wiring Diagram effectively:

- Start by identifying the key components in the diagram such as the battery, ignition switch, lights, and other electrical devices.

- Follow the wiring lines and symbols to trace the path of electricity flow from the power source to the various components.

- Pay attention to color codes and labels on the diagram to differentiate between different wires and components.

Using M Farmall Wiring Diagram for troubleshooting:

When faced with electrical problems on your M Farmall tractor, the wiring diagram can be your best tool for troubleshooting. Here’s how you can use the diagram effectively:

- Identify the specific circuit or component that is malfunctioning by referring to the wiring diagram.

- Trace the wiring connections to check for loose or damaged wires that may be causing the issue.

- Compare the actual wiring on your tractor with the diagram to spot any discrepancies or incorrect connections.

Safety is paramount when working with electrical systems and using wiring diagrams. Here are some important safety tips to keep in mind:

- Always disconnect the battery before working on any electrical components to prevent the risk of electric shock.

- Avoid working on electrical systems in wet or damp conditions to reduce the risk of short circuits.

- Use insulated tools and wear protective gear such as gloves and safety goggles when handling electrical components.

M Farmall Wiring Diagram

Farmall M Wiring Diagram – Wiringworks

[DIAGRAM] Farmall M Electrical Diagram – MYDIAGRAM.ONLINE

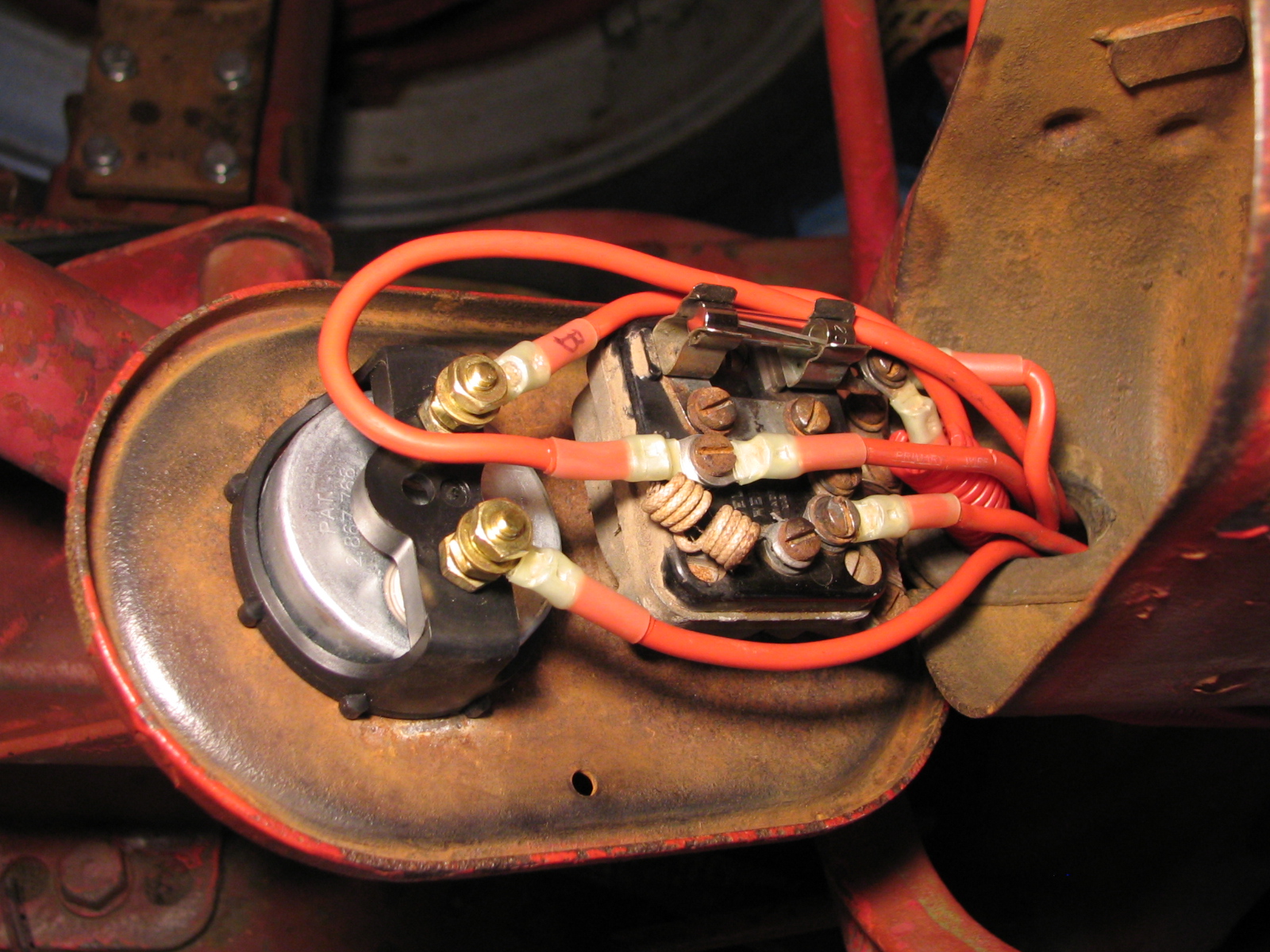

![M Farmall Wiring Diagram [DIAGRAM] Farmall M Electrical Diagram - MYDIAGRAM.ONLINE](http://photos.yesterdaystractors.com/gallery/uptest/a203933.jpg)

Farmall M Wiring Diagram

Farmall M Tractor Wiring Diagram

farmall m wiring diagram regulator

Super A Farmall Tractor Wiring Diagram